Polyamide 66 (PA66) is a product derived from hexamethylene and adipic acid. The main feature of this product is high resistance to abrasion and also higher resistance to temperature. While it has lower resistance to shock and shock and less water absorption compared to polyamide 6 (PA6).

In fact, polyamide 66 (PA66) is a better quality polyamide acidic resin. It is also ideal for use in automatic machines.

Polyamide 66 (PA66) has similar properties to polyamide 6 (PA6). Polyamide 66 (PA66) is also known as Nylon 66. Due to its good strength and rigidity, good surface quality and electrical resistance are common and popular materials used in industry.

Polyamide 66 (PA66) material is considered by craftsmen and industrial designers due to its suitable mechanical properties such as high strength and hardness, wear resistance and molding and easy production. For this reason, it is used in the electronics and auto parts industries, firefighting equipment and supplies, the body of industrial equipment and tools, and the cable manufacturing industry.

Easy molding is one of the advantages of this material, which can be molded and shaped at a temperature of 80-100 ° C. Of course, it should be noted that polyamide 66 (PA66) is machinable and in the end provides a good surface smoothness.

Advantages

- Erosion resistance even in heavy use.

- Hardness, high resistance to pressure and stress and its higher strength than polyamide 6 (PA6).

- Its application in automatic tools and machines has shown that it is easier to use as a chip for cutting strong fibers.

- Resistance to decay and wear and atmospheric factors.

- Durability and stability against moisture absorption.

- Certified EC10 / 2011 .FDA

Disadvantages

- Absorbs moisture. Although this value is lower than that of polyamide 6 (PA6), the mechanical properties and dimensions that follow are variable.

- Due to its greater dryness and hardness, it is less resistant to shock and impact than polyamide 6 (PA6).

Application

- Due to its high hardness, this superior feature has led to more consumption in the mechanical industry than polyamide 6 (PA6), and the resistance of gears, pulleys, wheels, shock absorbers and parts to impact and wear in general. It is more and more necessary to use it together with PAGX to work with automatic machines.

- Its proximity to products and food is unobstructed.

- Resistant to alkaline environment, mineral compounds and solvents.

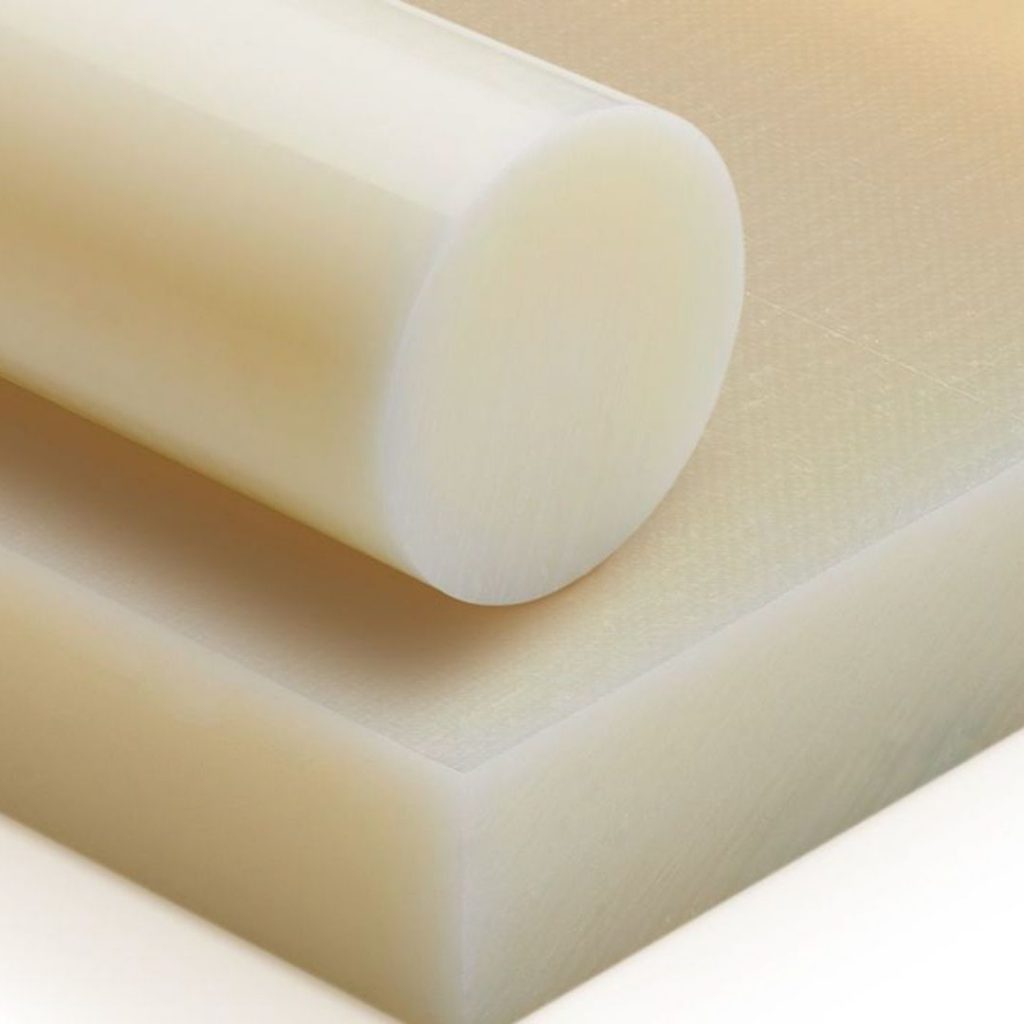

Polyamide 6.6 is supplied in the form of RODS in different dimensions and sizes.