In the automotive industry, engineering plastics such as polyurethane (PUR), Teflon (PTFE), Peak (PEEK) and polyamide (PA) are used in various parts of the vehicle due to their special properties.

Application of polyurethane (PUR)

Polyurethane (PUR) is a very efficient material for insulating walls, ceilings, pipes and even windows. In fact, polyurethane insulation (PUR) reduces energy consumption by up to 30%. Polyurethane thermal insulation (PUR) can be used in a wide variety of applications to save energy and prevent waste.

It is also used in car body and roof and reduces fuel consumption, weight reduction, increases comfort and increases corrosion resistance.

Application of Teflon (PTFE)

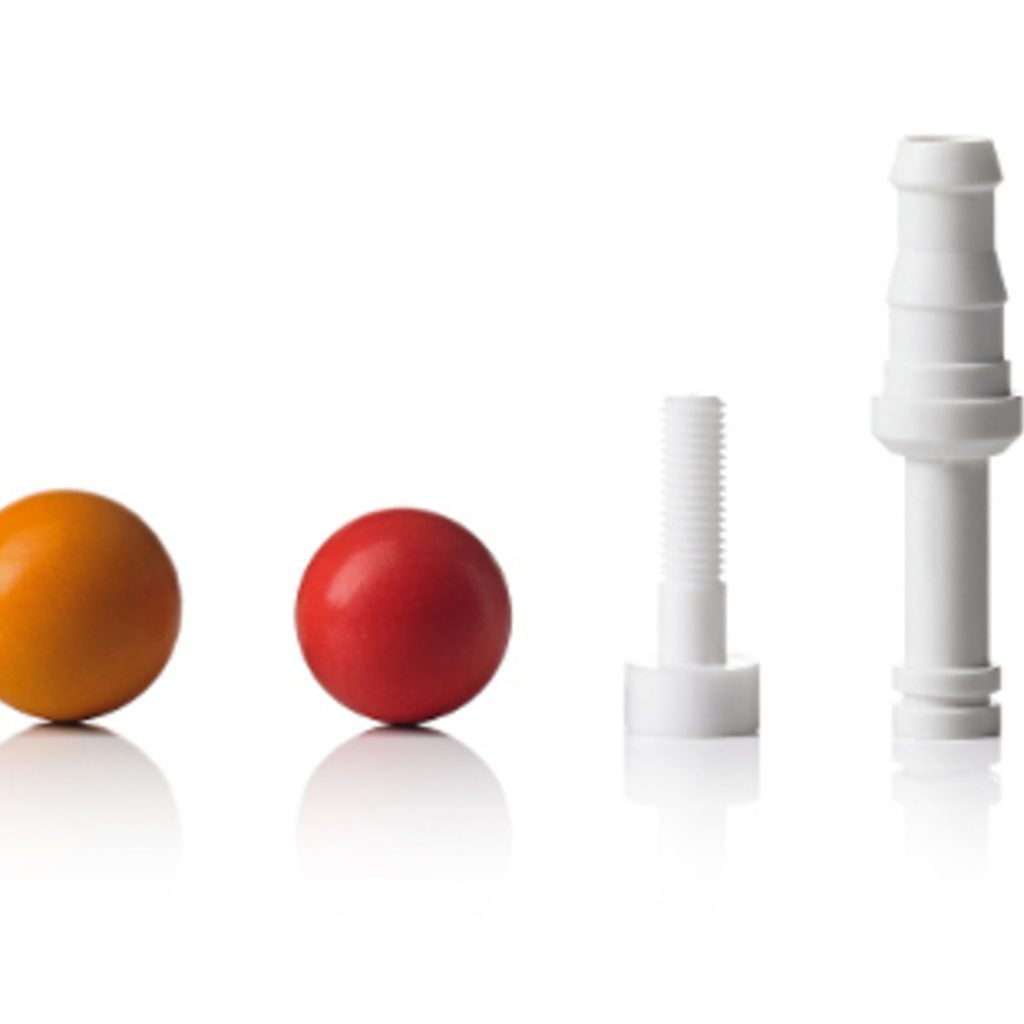

Teflon (PTFE) pipes are used in car engines because they have the lowest gas permeability.

Teflon (PTFE) with low friction coefficient, chemical resistance, thermal resistance and good mechanical properties is used in rims and injectors.

Application of PEEK

PEEK can reduce fuel efficiency and reduce greenhouse gas emissions in two ways:

1. Reduce energy losses due to overweight

2. Reduce friction losses in power. For example, a 68 percent weight reduction in gears reduces inertia by 78 percent and ultimately increases efficiency by 9 percent. The reason is low weight. That is, the moving masses are reduced and the friction losses are reduced, accelerating the response.

PEEKs are used in car rims due to their low coefficient of friction, chemical resistance, thermal resistance, good mechanical properties and light weight.

Application of polyamide (PA)

Polyamides (PA) are used in this industry as follows:

Extrusion and molded polyamide (PA) compounds can be used as an alternative to metal parts. Polyamide (PA) is used in car engine components because it is resistant to abrasion and because it is lighter and cheaper than aluminum. Also, because the inside of the polyamide (PA) pipe is smooth and soft, air flows well in it. Its lubricating properties make it suitable for gears and bearings.

Production of radiators, cooling impellers and valve caps using glass fiber reinforced polyamide (PA6GF 30)

Production of engine air manifold using fiber-reinforced polyamide product (PA6GF 30) heat resistant

Car door handles, lifting glass parts, mirror base, contactors and gears using fiber reinforced polyamide (PA6GF 30)

Application of polypropylene

Polypropylene is also used in the automotive industry in different ways:

Car interior trims include front, side console, dashboard using scratch-resistant talc reinforced polypropylene

Exterior parts of the car such as Pride bumpers, door sills and mud spreaders using different grades of talc reinforced polypropylene

In-engine components include brake fan base tray and other components using polypropylene reinforced with different percentages of glass fibers