Polytetrafluoroethylene (PTFE) is a synthetic molecular weight fluoropolymer (Tetrafluoroethylene (TFE) developed and registered by Du Pont de Nemours in 1938. PTFE was discovered during research on coolers. This powder could not be detected in acid, solvent or base and did not flow at melting temperature.

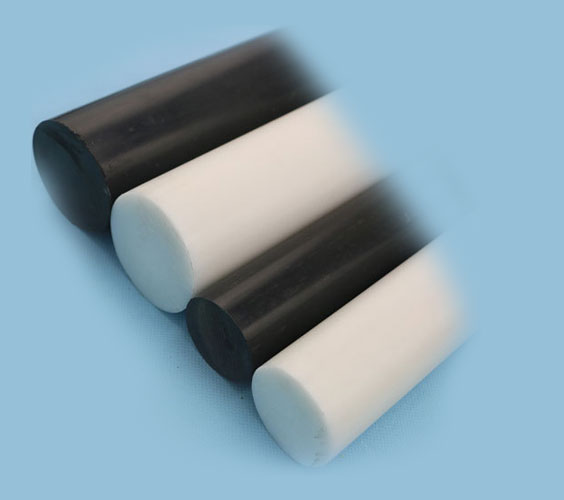

The following types of PA polyamides are available in sheets and bars:

Polyamide 6

Polyamide cast

Oil amide bridge

Polyamide 6.6

Polyamide mixed with 30% glass

Polystyrene POM has high strength and durability along with improved dimensional stability and ease of machining. Polystyrene POM, as a semi-crystalline material, is also characterized by low coefficient of friction and good abrasion properties, especially in humid environments.

UHMW1000 polyethylene has a standard for engineering polymers with a unique combination of wear and corrosion resistance, low friction level and impact strength.

UHMW1000 polyethylene is resistant to chemical penetration and moisture absorption and its key physical properties are maintained up to -30 ° C.

PUR polyurethane was developed in Germany during World War II. Its main application is in coatings, elastomers and foams. Elastomers are very resistant to abrasion. Rigid polyurethane foam is widely used as an insulating material due to its combination of low heat transfer and cost effectiveness.

Excellent mechanical performance allows parts to be designed with less weight, durability and strength. Thus PEEK peak is an alternative solution for metals in severe conditions. The thermal performance of PEEK peak, as well as its abrasion and chemical resistance, ensures longer life and integrity of components in harsh environments.

Polytetrafluoroethylene (PTFE) is formed by the polymerization of tetrafluoroethylene (TFE). The basic properties of PTFE are due to the very strong chemical bond between the carbon atom and the fluorine.

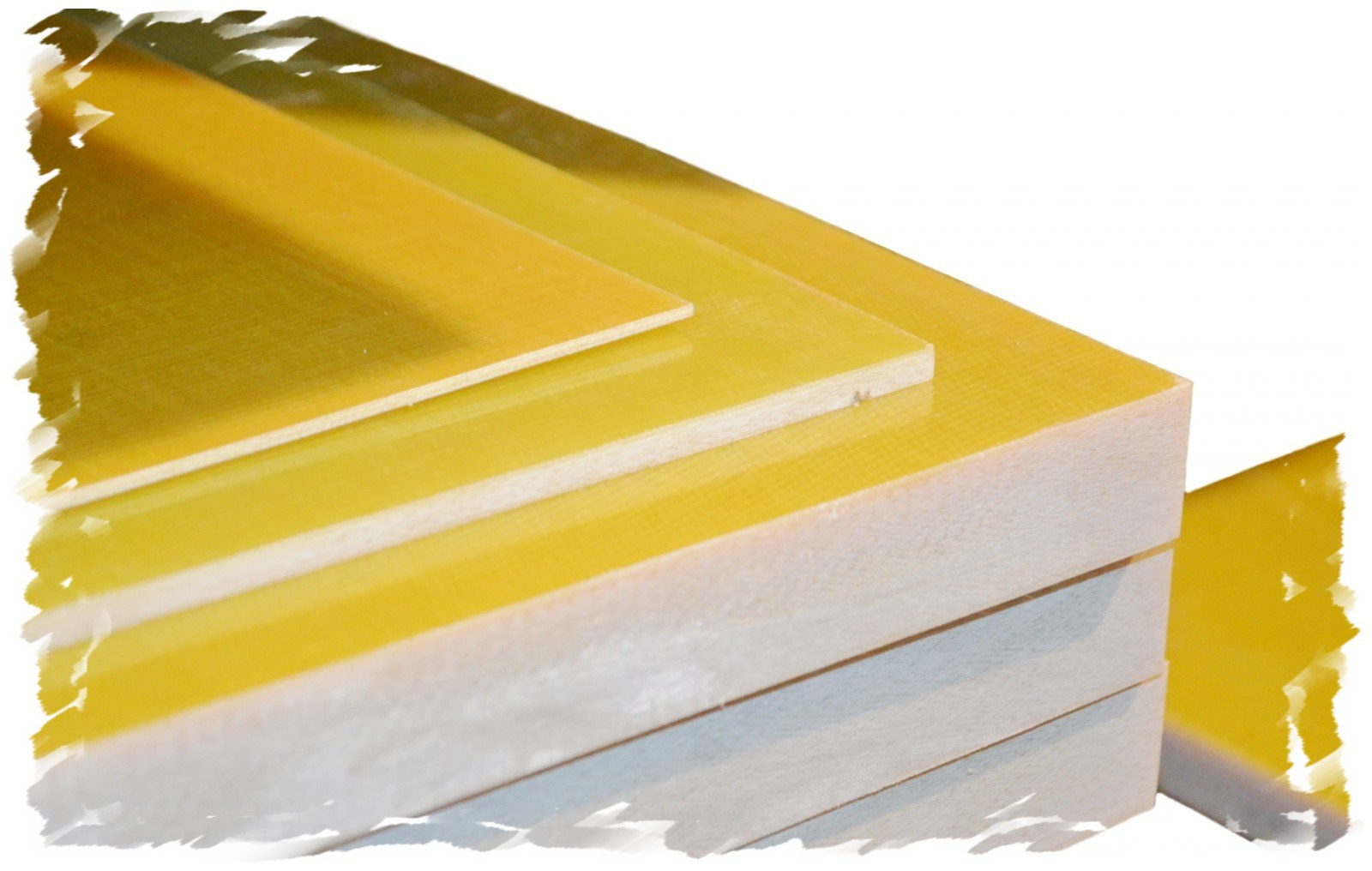

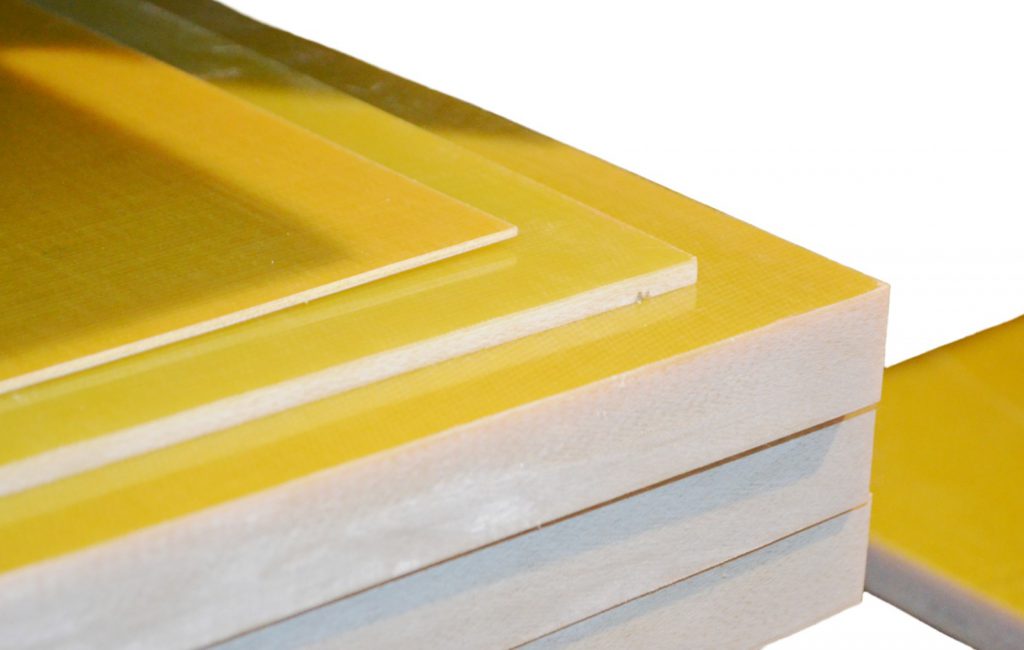

Epoxy fiberglass in green and yellow colors with different range of applications

PTFE gaskets have low chemical resistance and low contamination (FDA approved) for use in food.

PTFE is not recommended for liquid alkalis and flora

What is Virgin Teflon?

Teflon retains its properties even at very low temperatures. Therefore, it has many applications in important industries such as aerospace and industries that need to work at low temperatures, such as sealing liquid nitrogen tanks at -196 degrees and liquid hydrogen at -253.