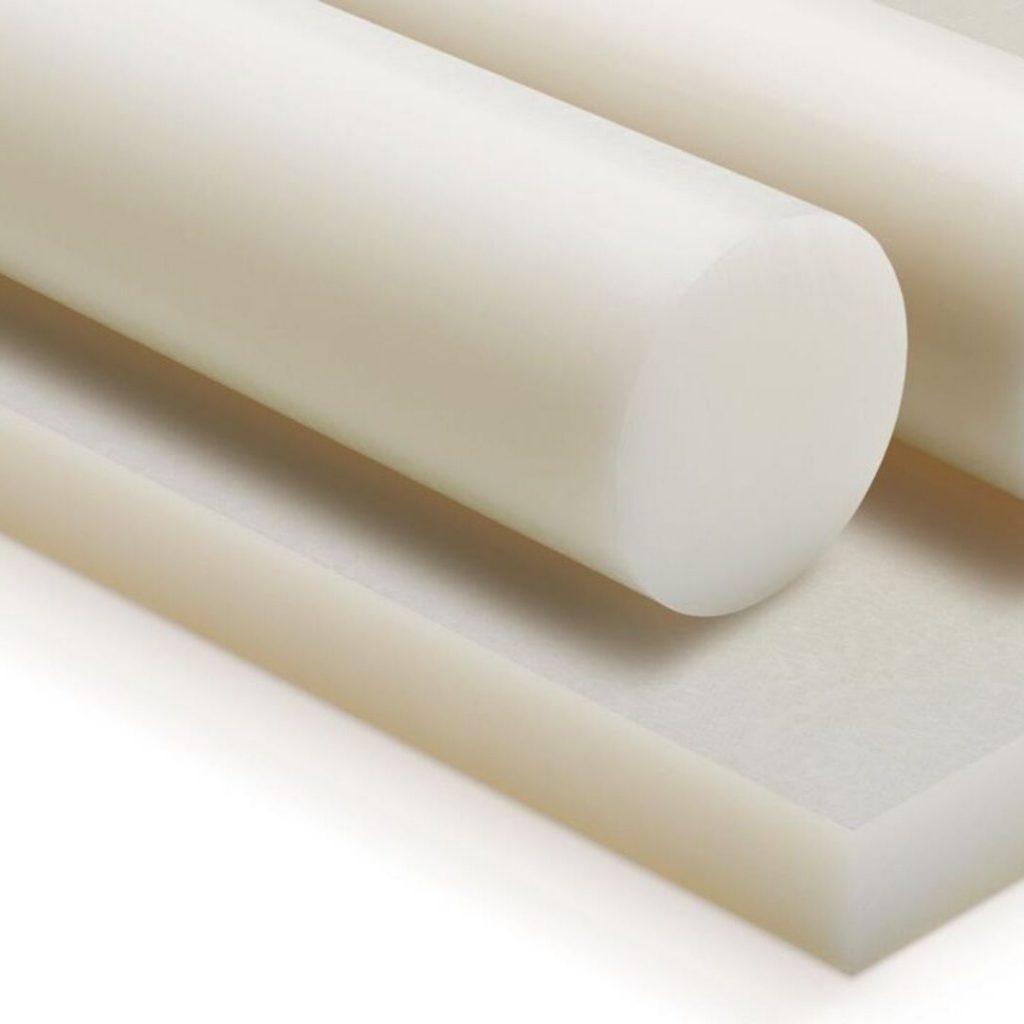

Semi-crystalline polymer polyamide 6 (PA6) has good general properties and excellent quality and price. The use of high viscosity raw materials to produce polyamide 6 (PA6) keeps the molds at an excellent level. The mechanical strength as well as the slip properties on the surface of polyamide 6 (PA6) are not comparable to other materials with low viscosity. The special baking process of this product gives this product dimensional stability and excellent machining.

Advantages

- Abrasion resistance: even in dust and harsh conditions due to this property is one of the best engineering plastics in this field.

- Hardness: High tensile and compressive strength and resistant to thermal shocks.

- Fatigue: One of the main properties of polyamide 6 (PA6) even in prolonged conditions.

- Self-lubrication: low friction coefficient and case suitable for use in sliding and rail parts.

- License to use in food industry

- Natural color

Disadvantages

- Polyamide 6 (PA6) is hydrated. This means that it loses its mechanical properties due to moisture absorption and changes its size.

- When dry, it is hard and hard, and due to moisture, shock resistance is low and efficiency is low.

- Good machining capability, but for machining by series lathe, due to the elasticity of the pleats, the work is difficult and the pleating

- suction machine had to be used.

Polyamide 6 natural and black (PA6) are produced and supplied in the form of SHEETS and RODS in different dimensions and sizes.