Micropowder tetrafluoroethylene powder (Teflon or PTFE) is formed by tetrafluoroethylene (TFE) polymerization. The basic properties of polytetrafluoroethylene (Teflon, PTFE) are due to the very strong chemical bond between the carbon atom and the fluorine.

Polytetrafluoroethylene (Teflon or PTFE) has a unique position in the plastics industry due to its lack of chemical penetration, heat resistance, excellent mechanical properties, dielectric, anti-adhesion and lower coefficient of friction than the working temperature And the amplitude of the pressure. These properties confirm the widespread use of these materials in all sectors of the industry.

Micro-polytetrafluoroethylene powder (Teflon or PTFE) is added to many materials to prevent friction and to reduce or avoid lubrication of parts made by molding or extrusion.

When mixing micro-polytetrafluoroethylene powder (Teflon or PTFE) with other materials, the speed and quality of the extrusion will increase and the surfaces will be resistant to scratches and chemical agents.

Microfluorocarbon powder (Teflon or PTFE) can replace molybdenum sulfate or graphite to reduce friction. Because it is completely mixed and does not accumulate at one point.

Mixing the material with micro-polytetrafluoroethylene powder (Teflon or PTFE), even at a low percentage, is effective in delaying the ignition and preventing the material from dripping when ignited.

Advantages

- Increase and improve self-lubrication

- Reduce coefficient of friction and wear

- Improving resistance to chemical agents

- High dielectric properties

- High temperature resistance

- Do not stick

- The color of the product does not change when mixed

- Micro Teflon powder (polytetrafluoroethylene, PTFE, PTFE) in the mixture with oil, increases the efficiency of the engine and in the mixture with grease, its great effect can be seen

- This powder has its own performance when mixed with paint and ink

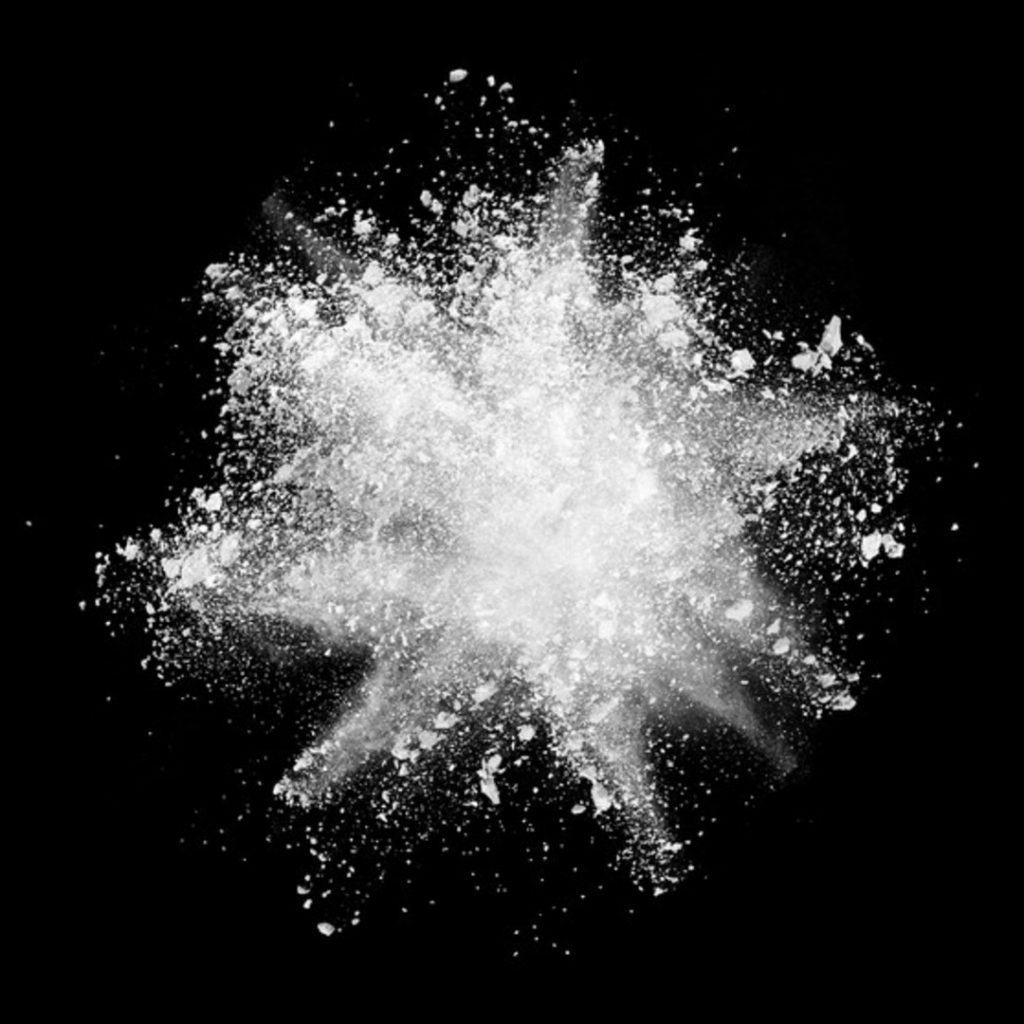

Micro powder PTFE is supplied in two forms of 1 to 5 microns and 25 microns with excellent quality.