Polyamide is mixed with 30% glass (PA6GF 30), polyamide 6 (PA6) is reinforced with the addition of 30% of glass fibers (glass) and graphite. This feature increases the resistance to abrasion, compression and bending.

Polyamide mixed with 30% glass (PA6GF 30) is suitable for gears and mechanical parts where high abrasion resistance is required.

Advatages

- Abrasion resistance, very high. This property of polyamide is enhanced by the addition of glass. Fiberglass polyamide (30 PA6GF) is one of the best abrasion resistant products.

- High compression strength and excellent abrasion resistance. In general, its excellent properties make it ideal for mechanical applications.

- Wear resistance, waterproof properties and good low temperature resistance.

Disadvantages

- When used with moving metal parts, wear occurs between plastic and metal parts due to the presence of glass or glass fibers.

Application

- Highly resistant to high pressure and abrasion, it is actually one of the best engineered plastics. These materials are especially suitable in gears with increased performance of mechanical components, as well as in construction equipment or applications in bulldozers and can be used without any excessive wear.

- Can not be in contact with food products.

- Even with changes in humidity, its electrical properties are always stable and usable. This plastic is in great demand with its good mechanical properties as well as its anti-weather performance.

- It is resistant in alkaline environment, mineral compounds and solvents.

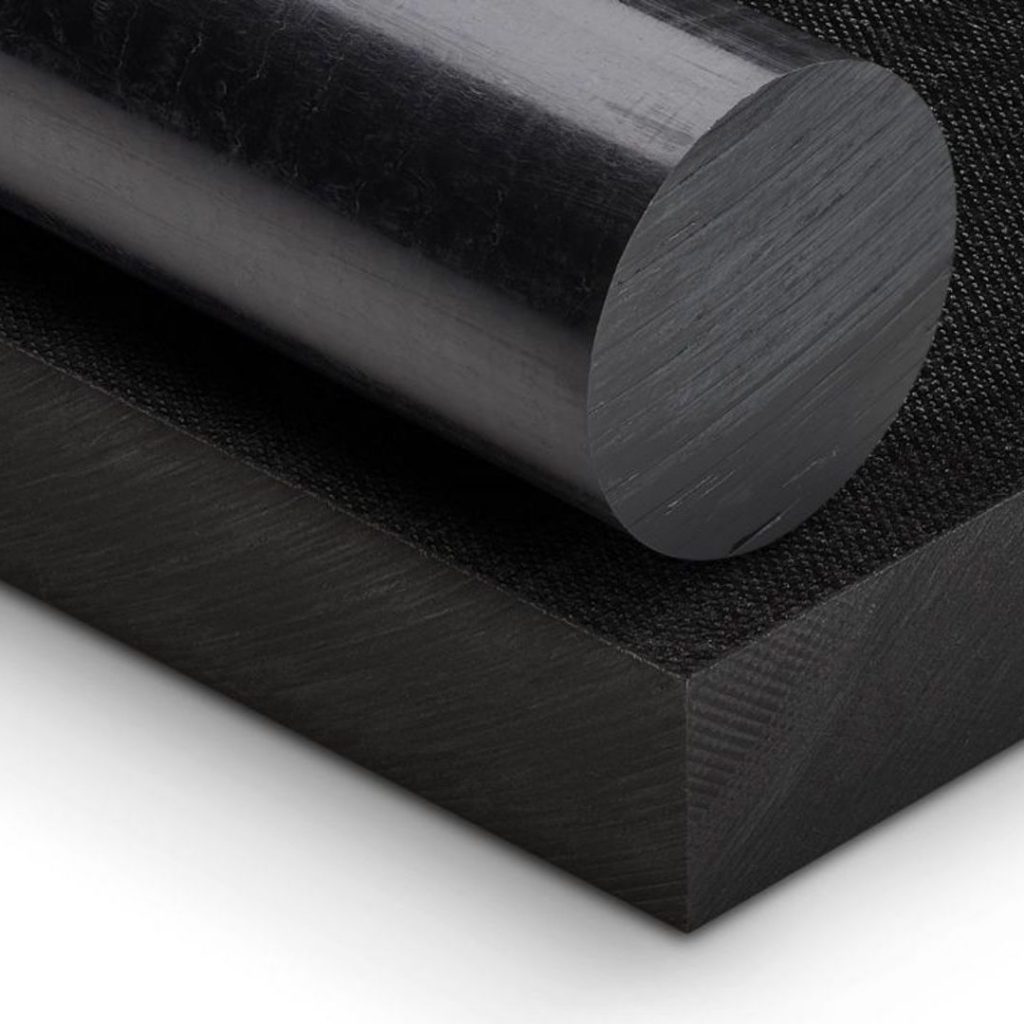

PA6GF 30 is supplied in the form of SHEETS and RODS in different dimensions and sizes.